📘 Six Causes of Plastic Yellowing

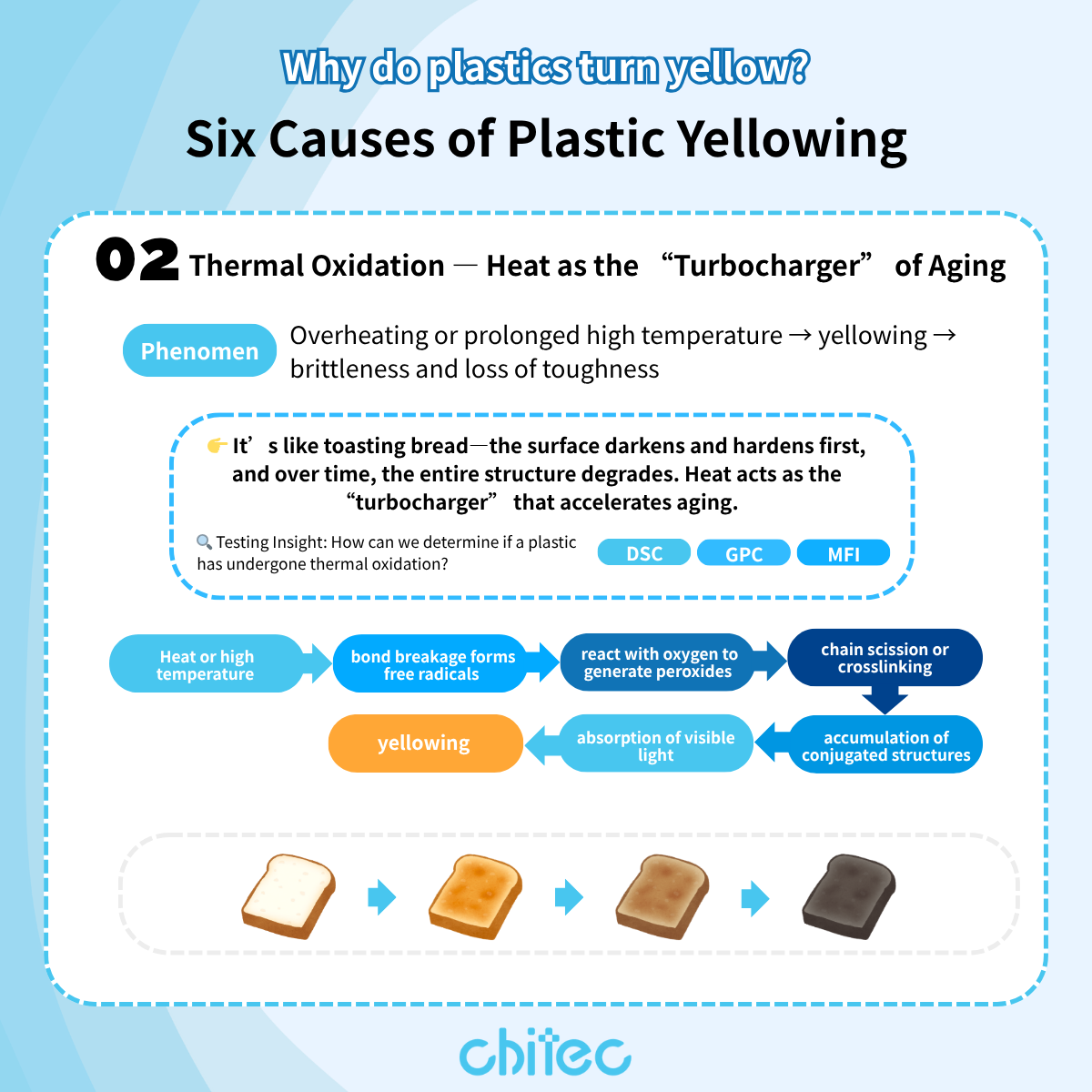

Part 2: Thermal Oxidation — Heat as the “Turbocharger” of Aging

🌡 Phenomenon

It’s not only sunlight that causes plastic to yellow—heat itself is also a powerful driver. If the processing temperature is too high, the material stays in the machine too long (“resin hold-up”), or recycled materials are repeatedly reprocessed, color darkening will gradually occur.

Even after products leave the factory, long-term exposure to high temperatures (for example, in server rooms or inside car cabins) will gradually lead to yellowing and embrittlement.

⚗️ Core Mechanism: When Heat Adds Fuel to the Fire

- Higher temperature accelerates reactions: Heat speeds up chemical reactions, promoting free radical formation and accelerating hydroperoxide decomposition.

- β-Scission: Free radicals break polymer chains, reducing molecular weight and mechanical strength.

- Crosslinking and Gelation: Some materials crosslink under heat, becoming harder and brittle, altering melt flow index (MFI).

🧩 Common Materials and Scenarios

- PP / PE: Overheating or excessive shear leads to yellowing then brittleness.

- PET: Moisture-sensitive; insufficient drying causes hydrolysis and color deepening.

- PC: Narrow processing window; long residence time or heat causes yellowing unless stabilized.

🔍 Testing Insights

- DSC: Detects crystallinity or melting changes after oxidation.

- GPC: Measures molecular weight drop or crosslinking rise.

- MFI: Scission increases MFI; crosslinking decreases it.

📘 There are four more articles in the “Plastic Aging Mechanism” series explaining yellowing, embrittlement, and gloss loss.

Read more –

Six Causes of Plastic Yellowing Part 1: Photo-oxidation

Six Causes of Plastic Yellowing Part 3: The “Side Effect” of Antioxidants

Six Causes of Plastic Yellowing Part 4: Additives and Impurities

Six Causes of Plastic Yellowing Part 5: Gas Fading

Six Causes of Plastic Yellowing Part 6: Inherent Aging Characteristics of Materials

The Science of Stability: How UV Absorbers Extend Material Performance

🔹Chitec Technology | The Expert in Anti-Aging Solutions for Materials

建議您使用以下瀏覽器觀看本網站,

要下載瀏覽器,請直接點擊以下:以獲得最佳瀏覽效果。