KSHOW 2025 Post-Show Report

Chitec Technology Showcases Precision Molecular Design in Material Stabilization at KSHOW 2025

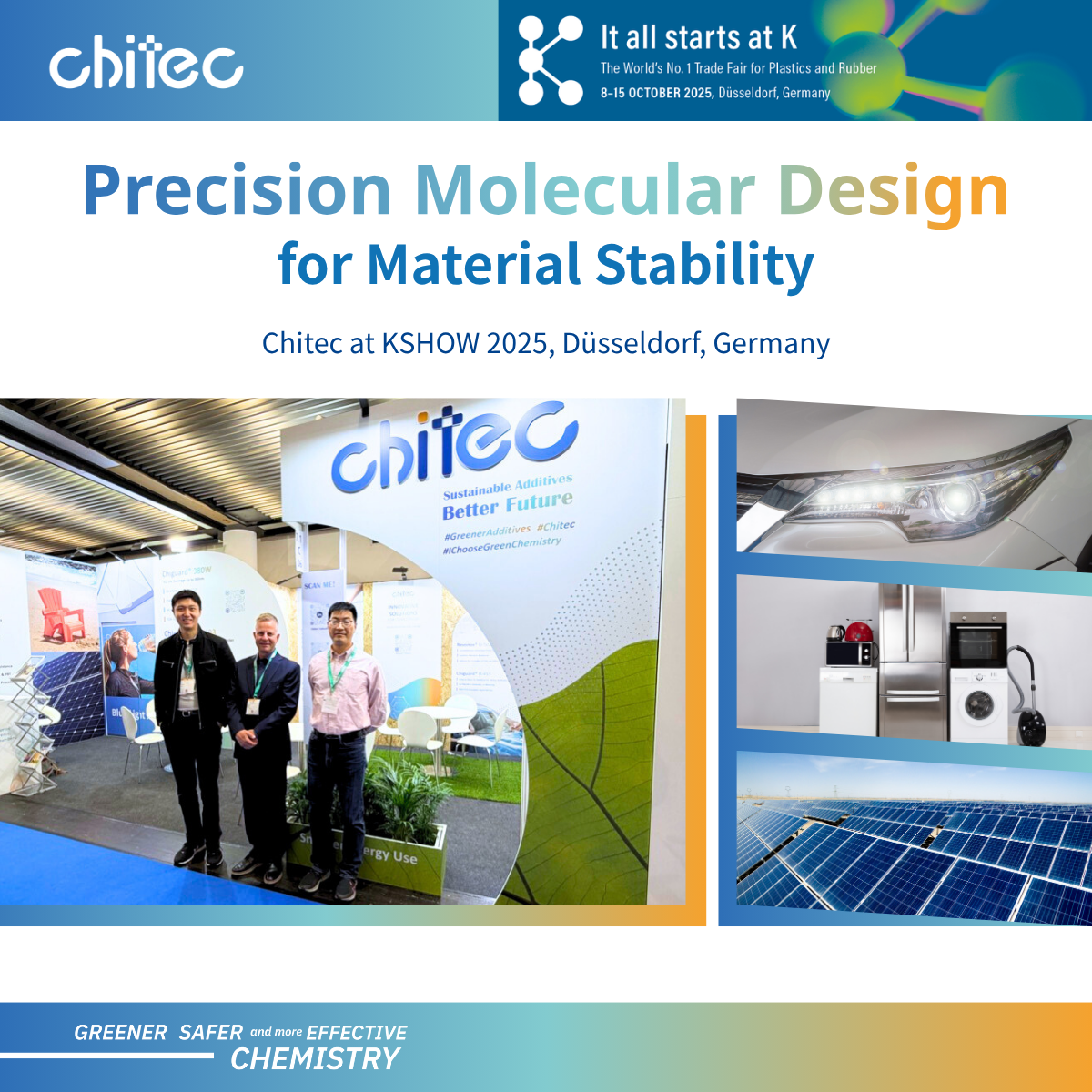

From October 8 to 15, 2025, CHITEC Technology participated in KSHOW 2025 in Düsseldorf, Germany, showcasing its precision molecular design approach for integrated light stabilization and antioxidant solutions.

The exhibition focused on three major themes: extended material lifespan, recyclability compatibility, and regulatory compliance. Centered on next-generation additive technologies, CHITEC demonstrated a forward-looking vision of stability and sustainability in material applications.

During the show, R&D teams, material manufacturers, and masterbatch partners from Europe, Asia, the Middle East, and Latin America visited the booth to discuss how to achieve the best balance between weatherability, environmental compliance, and performance durability.

Focus on Light Stabilization Technologies and Packaging Applications

R&D teams from multiple countries expressed strong interest in the Chiguard® light stabilizer series, particularly GA403 and 380W for their excellent blocking performance and long-term stability in high-transparency packaging and optical films.

Partners showed great enthusiasm for CHITEC’s 400 nm light-blocking performance achieved with minimal dosage, while also discussing the latest updates on EFSA / FDA certifications.

In addition, solid masterbatch solutions replacing liquid masterbatch became a key discussion point, regarded as a critical direction for improving formulation stability and recyclability.

High-Temperature Processing and Antioxidant Integration

In engineering plastics and high-temperature processing systems, Revonox® 608 utilizes a high-phosphorus molecular structure. Thermogravimetric analysis (TGA) shows a decomposition temperature above 386 °C. Even under high shear, high extrusion temperatures, or polymerization-stage addition, it maintains excellent stability and color performance.

The product has already been adopted in mass-production qualification programs by several partners, serving as a key component for enhancing process reliability and product durability.

Technical discussions also covered screw corrosion prevention, polymer compatibility, and dispersion control in nylon and glass fiber–reinforced PET systems, further improving long-term stability and processing consistency under high temperatures.

Polymerization-Stage Stabilization and Multilayer Applications

Global R&D teams exchanged insights on polymerization pre-mix stability control, DMHA compatibility, HALAL-certified applications, and light stabilization in multilayer structures.

Some nylon customers are evaluating the pre-blending of Revonox® 608 during the polymerization stage to enhance dispersion and final mechanical properties.

In coating and intermediate applications, the cost advantage and processing versatility of Chiguard® 1152 have also become key factors in technical assessments.

Additionally, some customers are specifically exploring the application potential of Revonox® 420V in polyolefin products and food packaging films, seeking further consultation on its feasibility.

Studies on pellet formulation design, hydrolysis resistance, and light stabilization optimization have also been included in ongoing collaboration and long-term testing programs with various technical teams.

Global Market Insights and Strategic Focus

The exhibition reflected the diverse market demands and strategic priorities for light stabilization and antioxidant technologies worldwide:

- Europe: Emphasizing sustainability and regulatory compliance, with a focus on recyclate compatibility.

- Asia: Focusing on high-temperature processing stability, low-migration antioxidant formulations, and waterborne technologies.

- Middle East & India: Actively adopting cost-effective stabilizer and antioxidant solutions with regulatory certifications, with mass-production implementation planned for 2026.

Deepening Technology and Sustainability Commitment

Through this exhibition, CHITEC has further strengthened its technical expertise in UV absorbers, antioxidant technologies, and polymer system integration. The company continues to collaborate with global R&D partners to advance materials that combine stability, regulatory safety, and sustainable manufacturing.

Looking ahead, CHITEC remains committed to its mission of extending material lifespan, reducing environmental impact, and improving process efficiency—driving reliable, high-performance, and sustainable material technologies for a better future.

Couldn’t Attend the Show?

We welcome inquiries regarding our products and technologies. Our team will be glad to assist you in finding the most suitable solution.

📩 Contact us: sales@chitec.com