Revonox® 608: Antioxidant Solution for Thermal Degradation, Discoloration, and Black Specks in Polymers

The Three Major Challenges in Polymer Processing

In real-world polymer production, the most frequent and costly challenges rarely stem from a single factor. Instead, they arise from the chain reaction of heat, oxygen, and moisture acting together. During extrusion or injection molding, high temperatures and high shear drive polymer chains into an auto-oxidation cycle, leading to rapid accumulation of hydroperoxides. As a result, polymers suffer from deepened color, yellowing, and even a decline in mechanical properties.

Even when switching to different grades of phosphite antioxidants, issues often remain due to their insufficient heat resistance or volatility at high temperatures, resulting in compromised appearance and properties.

Another persistent issue for quality control and production teams is hydrolysis under humid or re-moisture conditions. Many conventional phosphites gradually decompose in the presence of moisture, and the resulting byproducts accumulate within the polymer, ultimately forming black specks or gel defects. For transparent parts, films, or applications requiring high surface quality, black specks cause visible spots or particles; during processing, gels may interfere with melt flow, causing extrusion breakage, die clogging, or molding defects, compromising line stability and efficiency. More critically, black specks and gels represent structural inhomogeneities that often act as stress concentration points. Over time, these hidden defects can initiate cracks, leading to brittle failure or shortened service life.

In addition, manufacturers of kitchen appliances, packaging, and food-contact materials face further pressure from additive migration and regulatory compliance. Meeting low-migration requirements, REACH regulations, and food-contact approvals often determines whether a formulation can pass customer validation and achieve rapid market entry.

The Solution: Revonox® 608 – Cutting Polymer Degradation at the Source

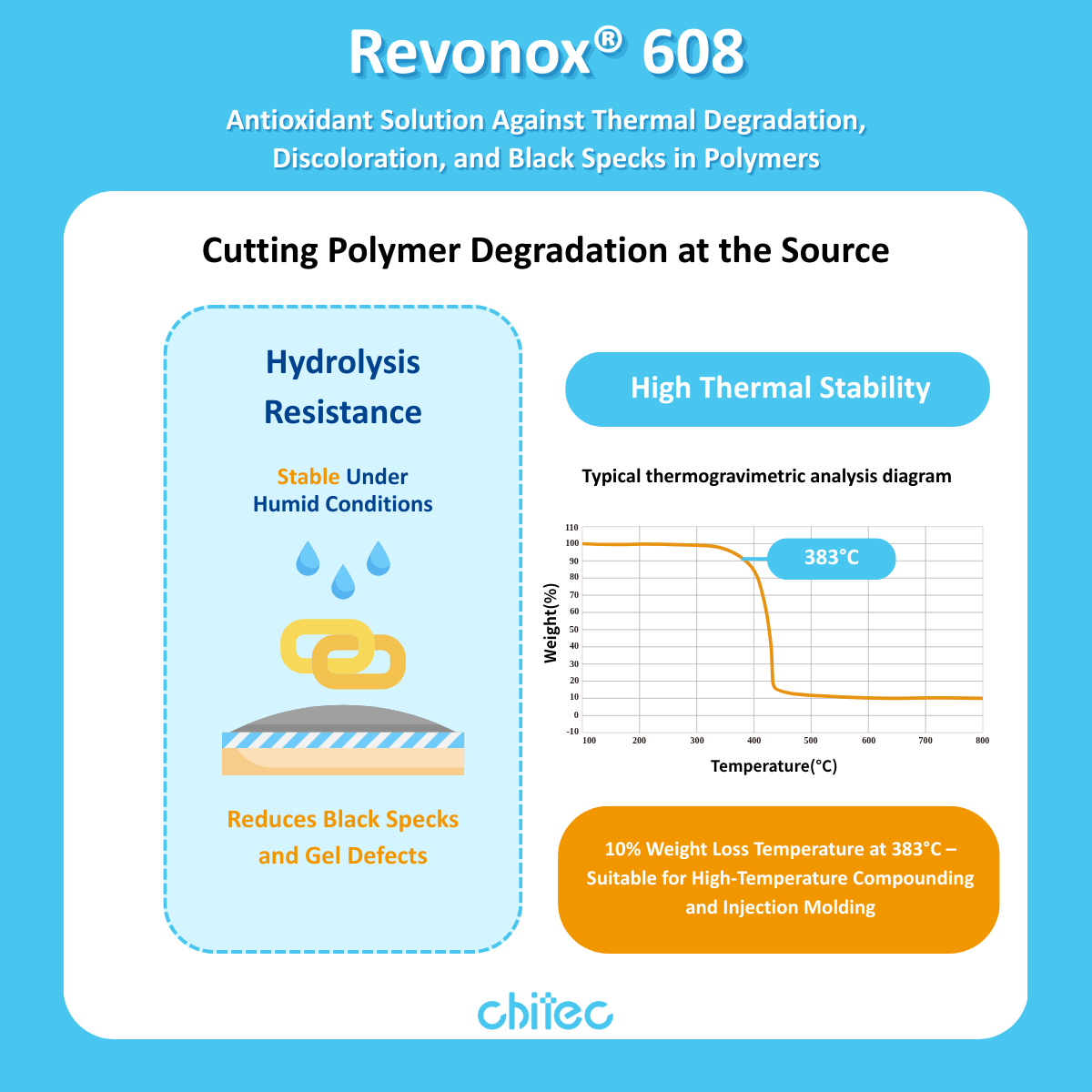

Revonox® 608 belongs to the spiro phosphite antioxidant family, renowned for its high phosphorus content and superior efficiency. Unlike other spiro phosphites, it offers outstanding hydrolytic stability, overcoming the inherent hydrolysis weakness of spiro structures. Even under humid conditions, it performs reliably, significantly reducing the formation of black specks and gels.

Its chemical name is bis(2,4-diisopropylphenyl) pentaerythritol diphosphite, with a phosphorus content of 7.3%, far higher than the 2–5% typical of conventional phosphites. This means Revonox® 608 provides more active reactive sites per unit weight, enabling faster and more complete removal of hydroperoxides during polymer degradation. As a result, it delivers exceptional antioxidant efficiency even at lower dosages.

Superior Thermal Stability and Color Protection

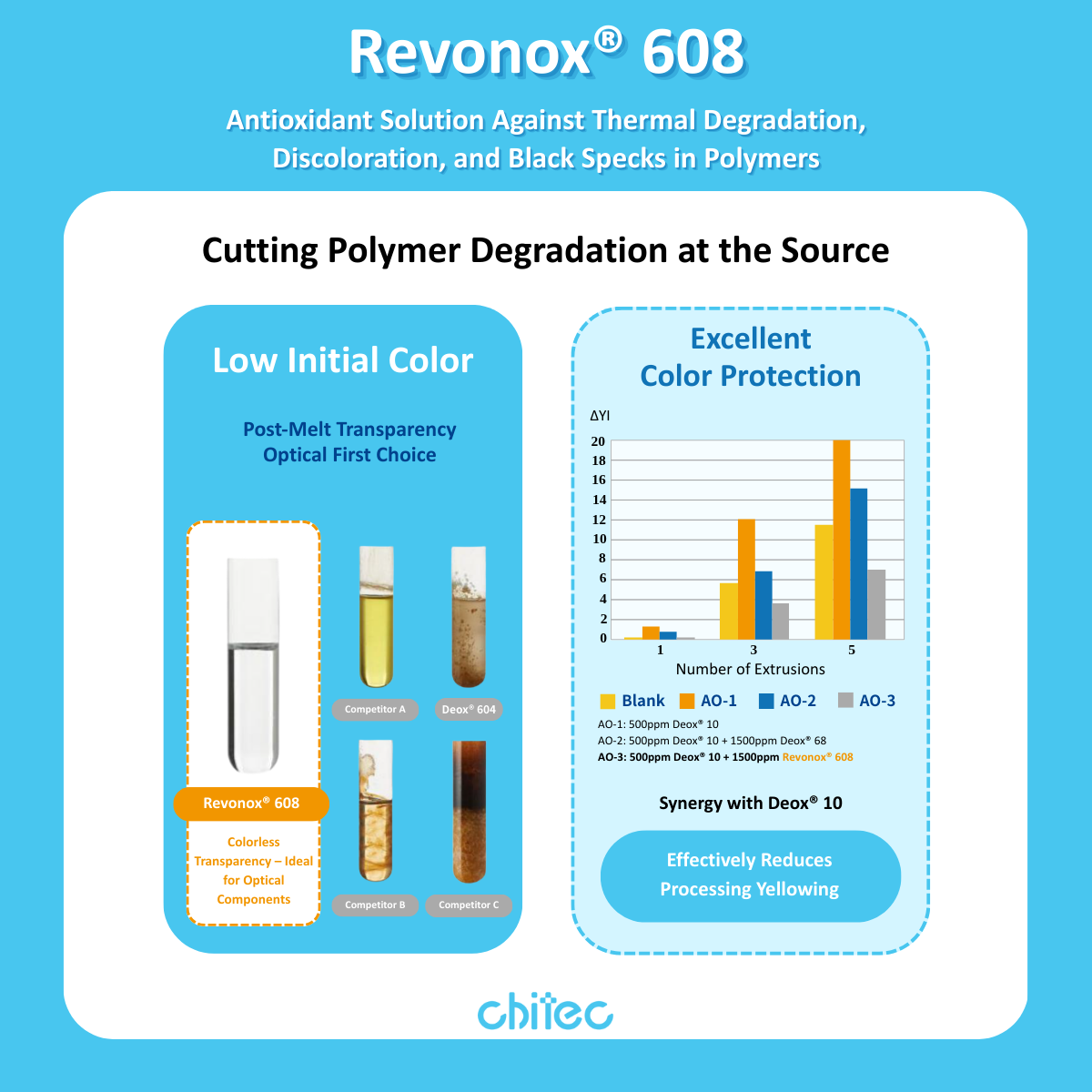

In terms of color stability, Revonox® 608 demonstrates remarkable advantages. The picture above illustrates color change (ΔYI) in PET processed at 280°C after 1, 3, and 5 extrusion cycles:

• AO-1: 500 ppm Deox® 10 only. Rapid yellowing occurred, with ΔYI approaching 20 after five cycles – the worst performance.

• AO-2: 500 ppm Deox® 10 + 1,500 ppm Deox® 68. Improvement observed, but ΔYI still reached around 15 after five cycles.

• AO-3: 500 ppm Deox® 10 + 1,500 ppm Revonox® 608. Best performance, with ΔYI maintained below 7 even after multiple extrusion cycles, demonstrating significantly superior color stability.

This experiment confirms that Revonox® 608 offers excellent color protection under high-temperature processing, making it particularly well-suited for engineering plastics requiring multiple processing steps or long residence times, such as PET, PC, and nylon.

In terms of thermal stability, Revonox® 608 also delivers market-leading performance. Its 10% weight loss temperature reaches 383°C, far higher than the heat resistance limits of conventional phosphites. In high-temperature systems such as polycarbonate, polyester, and polyamide, Revonox® 608 not only avoids decomposition or volatilization but also ensures melt-flow stability and consistent color.

From Engineering Plastics to General Resins

In engineering plastics, Revonox® 608 demonstrates excellent compatibility with polycarbonate (including branched PC), polyesters, nylon, and polyetherimide. These polymers are typically processed at temperatures of 280–300°C or higher, where conventional phosphites decompose or volatilize, severely reducing antioxidant efficiency. By contrast, Revonox® 608, with its outstanding thermal stability and transparent, colorless melt, maintains melt flow and color stability even under high shear or long residence times, reducing risks of yellowing, streaks, and melt fluctuations. This provides reliable protection for applications requiring superior appearance and performance.

For polycarbonate (PC), Revonox® 608 has shown superior color stability in antioxidant efficiency tests compared to competitor products. This feature is particularly critical for high-transparency optical parts, structural transparent components, as well as premium appliances and automotive interiors. For manufacturers, such differentiation not only ensures consistent product quality and appearance but also translates directly into competitive advantage and brand value.

In general-purpose plastics such as PP, PVC, PS, POM, ABS, and PMMA, Revonox® 608 helps preserve mechanical and physical properties over time by reducing embrittlement caused by thermal oxidation. This is especially important for products requiring multiple melt reprocessing or long-term thermal aging validation, where both appearance and toughness must be maintained.

Revonox® 608 has a melting range of 225–246°C. This is advantageous for high-temperature engineering plastics, as it retains its structure and activity during compounding and molding without decomposition or deactivation. However, for lower-processing-temperature polymers (such as many polyethylenes and polyurethanes), its dispersion may be limited. If your production relies mainly on low-temperature polyolefins and you wish to evaluate Revonox® 608’s applicability, the Chitec technical team is ready to assist in developing the most suitable application strategy.

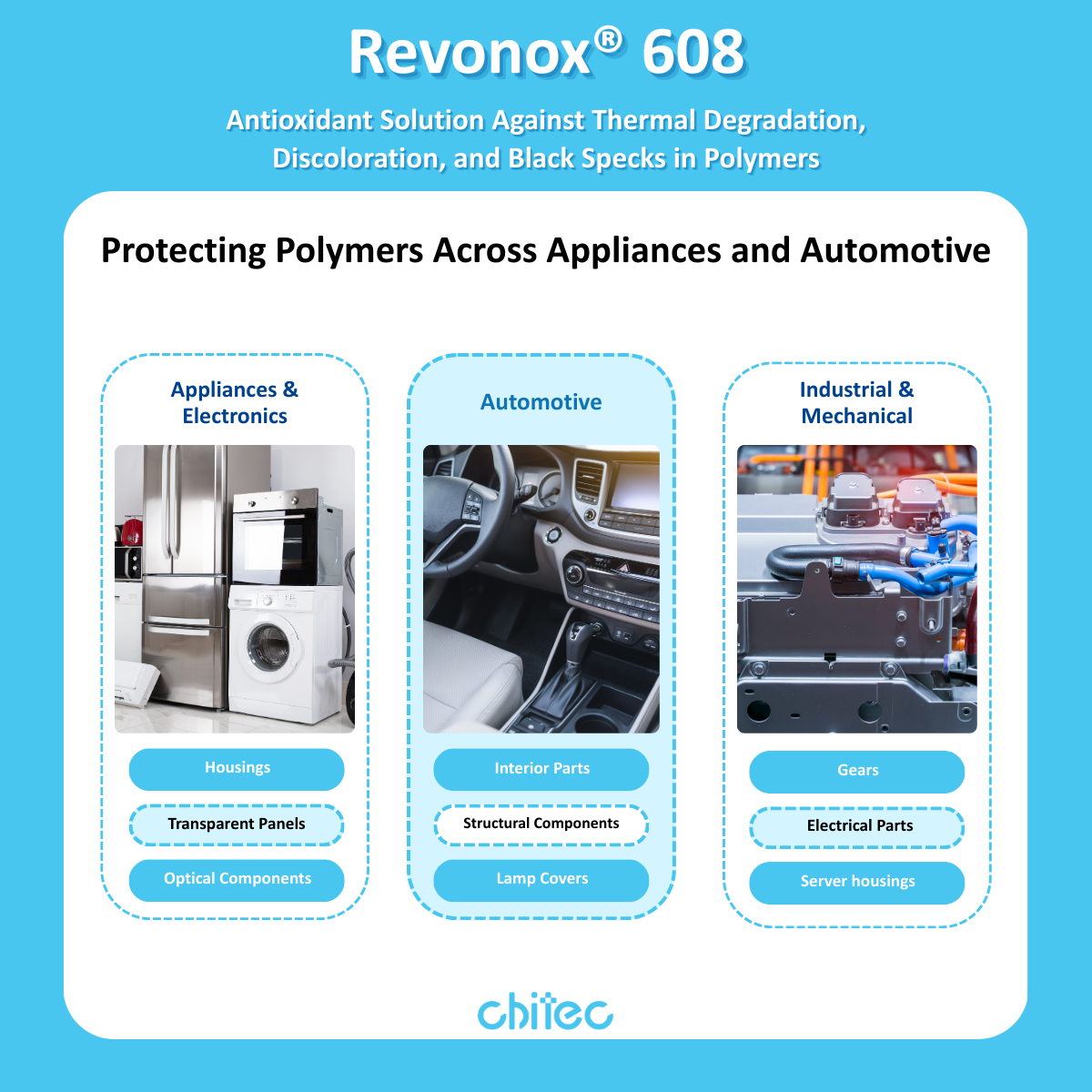

Applications

- Appliance housings: washing machines, refrigerators, ovens, dryers, dishwashers

- Premium kitchen & household appliances: kettles, coffee machines, blenders

- Electronic devices: housings, transparent panels

- Optical components: sheets, light covers, lenses

- Interior parts: dashboards, instrument panels, trim panels

- Structural components: connectors, clips, fasteners

- Lighting & transparent parts: lamp covers, decorative elements, sunroofs

- Under-the-hood components

- Industrial parts: gears, pulleys, connectors

- Electrical parts: plugs, connectors, insulation materials

- Powder coating applications: surface protection of coated parts

- Server housings and industrial computer casings

Discover How Revonox® 608 Can Enhance Your Polymers

Contact our team for professional support and tailored formulation advice.