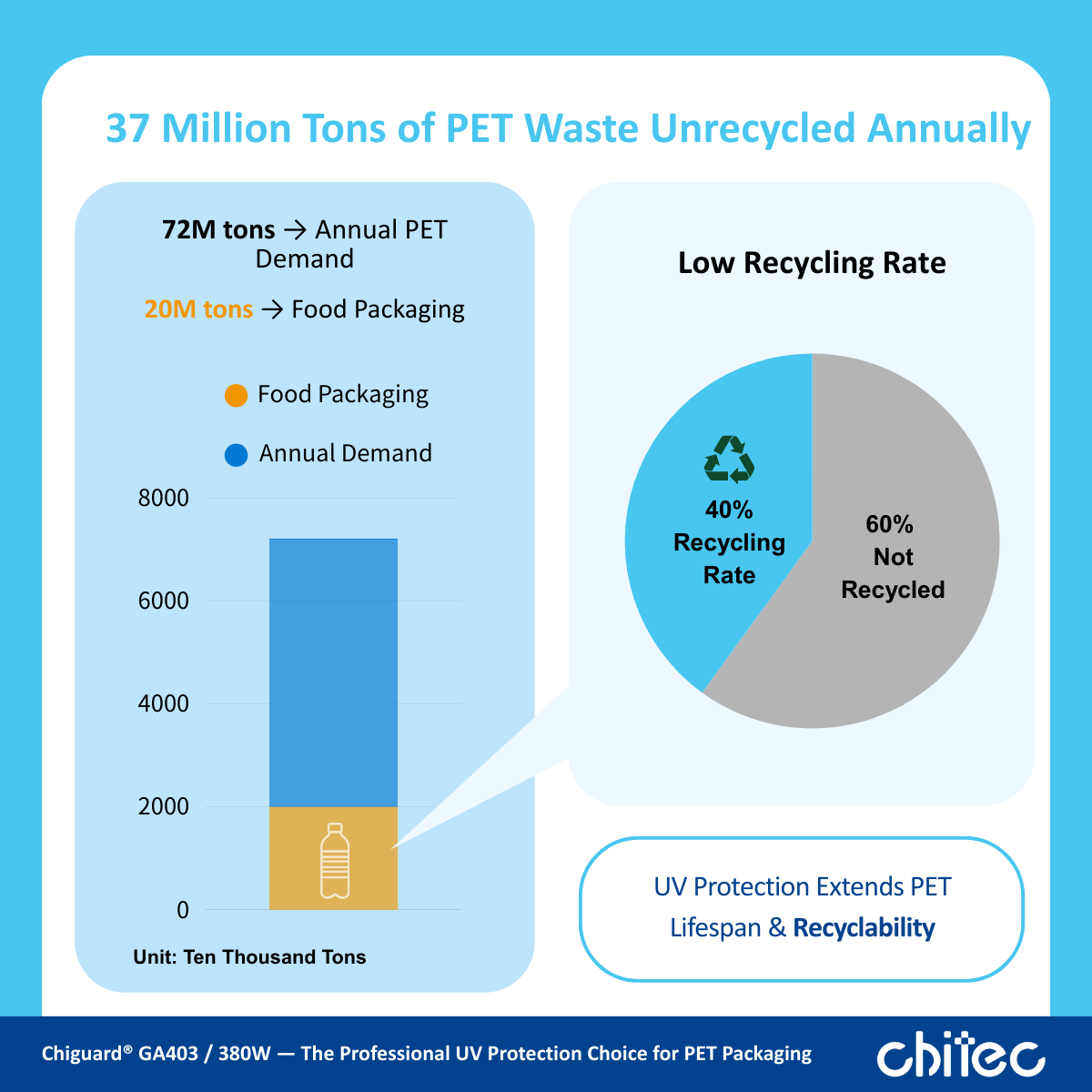

PET Packaging Market: Rapid Growth Amid Emerging Challenges

PET (polyethylene terephthalate) has long been a core material for food and beverage packaging due to its transparency, lightweight nature, and recyclability. However, with global usage continuing to rise, the market faces several pressing challenges: insufficient recycling rates, photodegradation affecting material durability, and performance decline during reuse.

rPET:

Opportunities and Challenges in the Circular Economy

Every consumed PET bottle has the potential to be more than just waste — it can be given a new life. This is rPET (Recycled PET), a circular material that is collected, washed, pelletized, and reprocessed for use in new products.

Its greatest value lies in the fact that for every ton of rPET used, carbon emissions can be reduced by up to 60% compared to virgin PET.

However, during repeated recycling and processing, rPET often faces issues such as yellowing, reduced clarity, and strength degradation. These defects limit the proportion of rPET that can be used in food-grade applications, forcing brands to blend in more virgin materials and diminishing the effectiveness of circular economy initiatives.

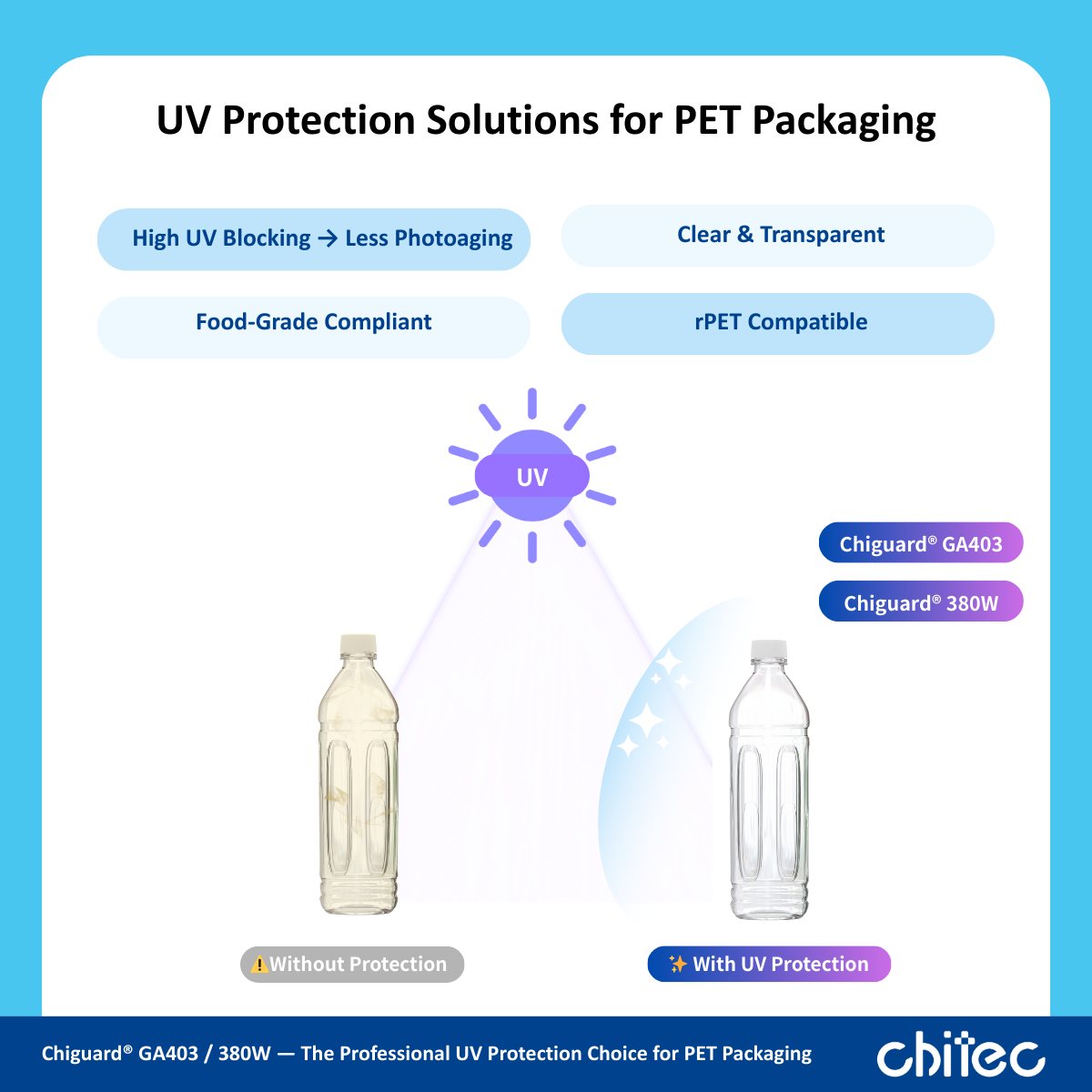

Our Solution: Chiguard® GA403 and Chiguard® 380W — A UV Protection System Tailored for Food-Grade PET

By starting from the materials side and balancing protection, transparency, and processing stability, the formulation delivers consistent performance in high-standard applications such as carbonated beverages, functional drinks, and light-sensitive foods.

- Key Features: Exhibits extremely high absorption in the UV-A spectrum.

- Performance: In a 1 mm PET film with 1500 ppm added, it completely blocks UV light below 405 nm, with minimal impact on initial color, maintaining a clear and transparent appearance.

- Migration Resistance: Passed migration tests with 10% ethanol, 3% acetic acid, and vegetable oil simulants, showing no detectable migration; features low solubility and high compatibility with various plastics.

- Heat Resistance: Thermal stability above 300°C, suitable for high-temperature processing of PET and PC materials.

- Best Applications: When combined with 380W, it forms a long-lasting, weather-resistant UV protection system with low color shift.

▷▷Learn more about Chiguard® GA403 A Broad Spectrum and Highly Effective UV Blocker

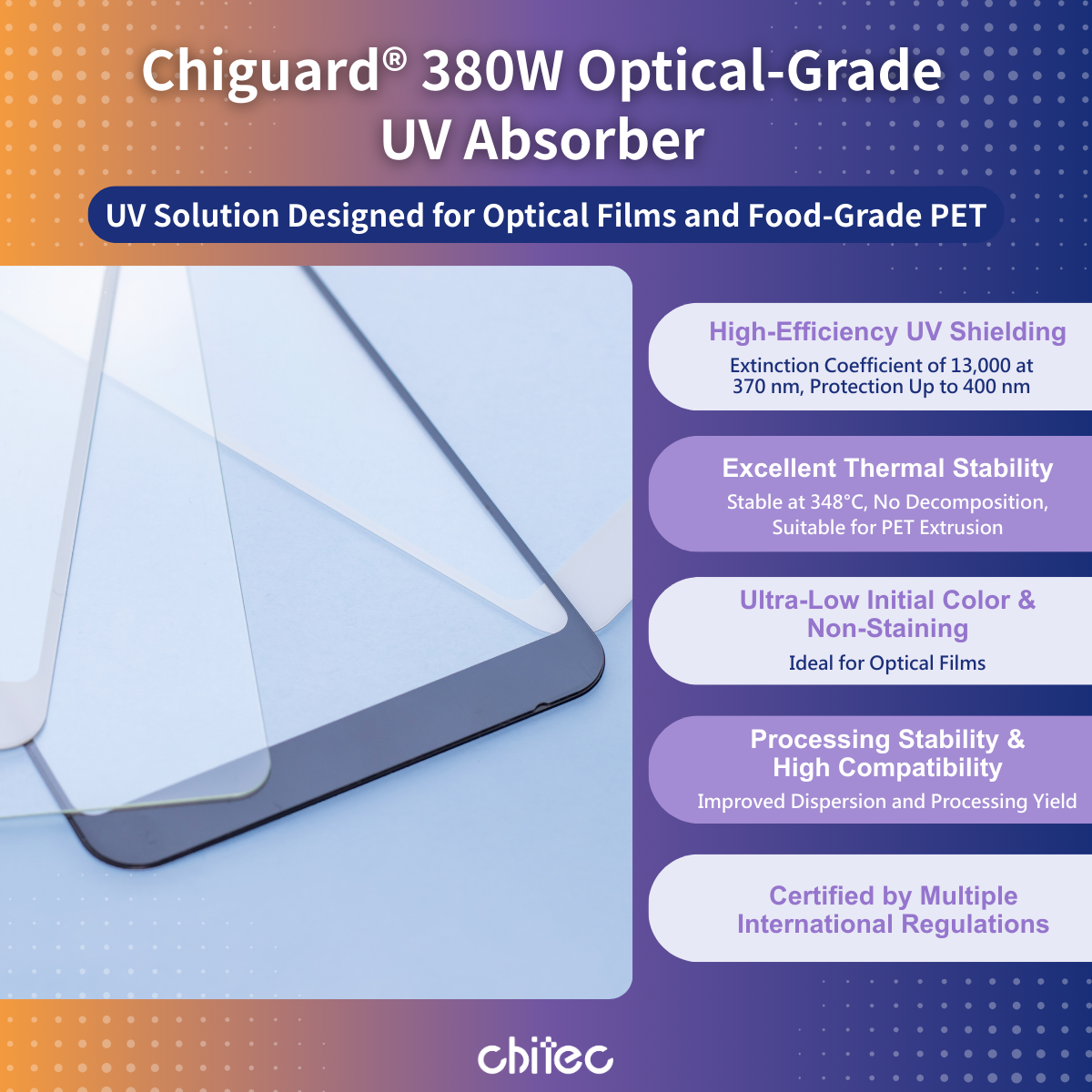

- Key Features: Optical-grade UV absorber with high transparency, excellent weatherability, and compliance with multiple international food-contact regulations.

- Performance: Extinction coefficient of 13,000 at 370 nm, enabling full-spectrum UV protection close to 400 nm even at low dosages.

- Heat Resistance: Thermogravimetric analysis (TGA) shows a 10% weight loss temperature of approximately 348°C, ensuring stability without decomposition during high-temperature processes such as PET extrusion and film stretching.

- Appearance Advantage: Very low initial color (YI ≈ -3 ~ -4), non-staining, and no impact on transparency.

- Processing Compatibility: Highly compatible with PET resins; even at high concentrations, it disperses uniformly without precipitation, ensuring stable appearance and high processing yield.

- Best Applications: Particularly suitable for optical films, transparent food packaging, and PET bottles.

▷▷Learn more about Chiguard® 380W Optical-Grade UV Absorber|UV Solution Designed for Optical Films and Food-Grade PET

Driving Sustainability and Competitiveness from the Materials Side

While recycling technologies for fibers are still evolving, upgrading the quality of food-grade packaging can start from the materials side. Introducing compliant and efficient UV absorbers helps maintain product quality, extend packaging lifespan, and reduce waste and losses, all while enhancing a brand’s sustainability performance and market competitiveness under regulatory compliance.

The combination of GA403 × 380W achieves a practical balance between protection, transparency, and processing stability, making it especially suitable for carbonated beverages, functional drinks, and light-sensitive foods that demand high standards in appearance and preservation.

※References:

寶特瓶:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年) - 日商環球訊息有限公司 (GII)

聚酯材料化學解聚與應用:材料世界網

Next Step

Chitec Technology has been deeply engaged in functional additives, providing high-efficiency, stable UV absorbers that comply with international food-contact regulations. We help food and beverage packaging manufacturers find the optimal balance between quality, shelf life, and sustainability.

We can provide customized recommendations and testing plans tailored to your resin grade, processing conditions, and appearance goals.

-

Request formulation recommendations and dosage ranges

-

Evaluate applications integrated with rPET

-

Obtain compliance documents and test data (TGA, migration, YI)

-

Request samples