Chiguard® 5405: Precision UVA Solution for Powder Coatings – Designed for Demanding Environments and Long-Term Performance

In high-performance coating systems such as automotive primers, industrial finishes, and outdoor construction materials, UV exposure is a primary cause of coating failure. Without proper stabilization, coatings are prone to discoloration, gloss loss, chalking, and cracking. This significantly shortens their service life and increases maintenance costs.

Chiguard® 5405 is a solid-state Hydroxyphenyl Triazine (HPT) UV absorber developed specifically for powder coatings, particularly GMA-based acrylic systems and other polar coating chemistries. It offers durable UV protection while maintaining both structural integrity and surface aesthetics over extended outdoor exposure.

5 Key Technical Advantages of Chiguard® 5405

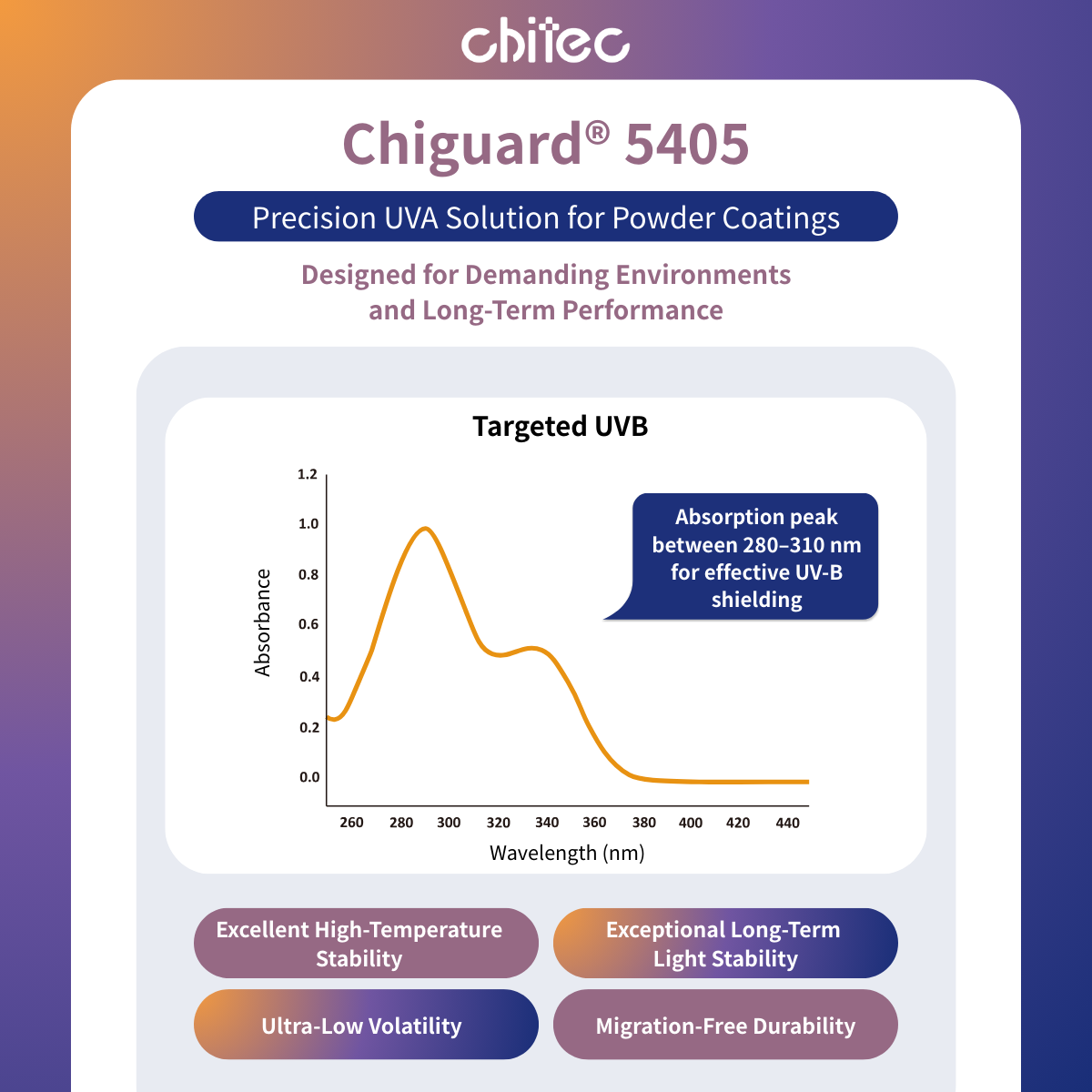

1. Precision UV-B Targeted Protection

-

Built on Hydroxyphenyl Triazine (HPT) chemistry

-

Absorption peak concentrated between 280–310 nm for highly effective UV-B shielding

-

Maintains stable absorption across 320–380 nm (UV-A range) to significantly slow coating degradation and preserve gloss over time

2. Excellent High-Temperature Stability – Designed for GMA Powder Coatings

-

Melting point: 70–77°C → Enables rapid melt-in and uniform dispersion during powder coating extrusion

-

Decomposition temperature: >280°C @101.3 kPa → Retains chemical stability after high-temperature curing without compromising coating performance

This not only improves production efficiency but also ensures a fine, smooth, and premium surface finish

3. Exceptional Long-Term Light Stability

Engineered for prolonged outdoor exposure and harsh environments, maintaining both structural integrity and visual appearance for years

4. Ultra-Low Volatility

-

Volatile content ≤0.5% (tested at 105°C for 2 hours)

Delivers consistent UV protection even under high processing temperatures and extended service conditions

5. Migration-Free Durability

Molecular structure locks firmly into the coating matrix, effectively preventing additive migration that could lead to gloss irregularities, haze, or loss of UV resistance

Why GMA-Based Powder Coatings Need Advanced UV Stabilization

GMA (Glycidyl Methacrylate)-based powder coatings are acrylic systems known for excellent weatherability and mechanical strength. They are widely used in:

- Architectural aluminum extrusions

- Outdoor equipment enclosures

- Corrosion-resistant industrial structures

These applications demand UV stabilizers that can endure prolonged exposure while integrating seamlessly into the formulation without affecting cure or film performance.

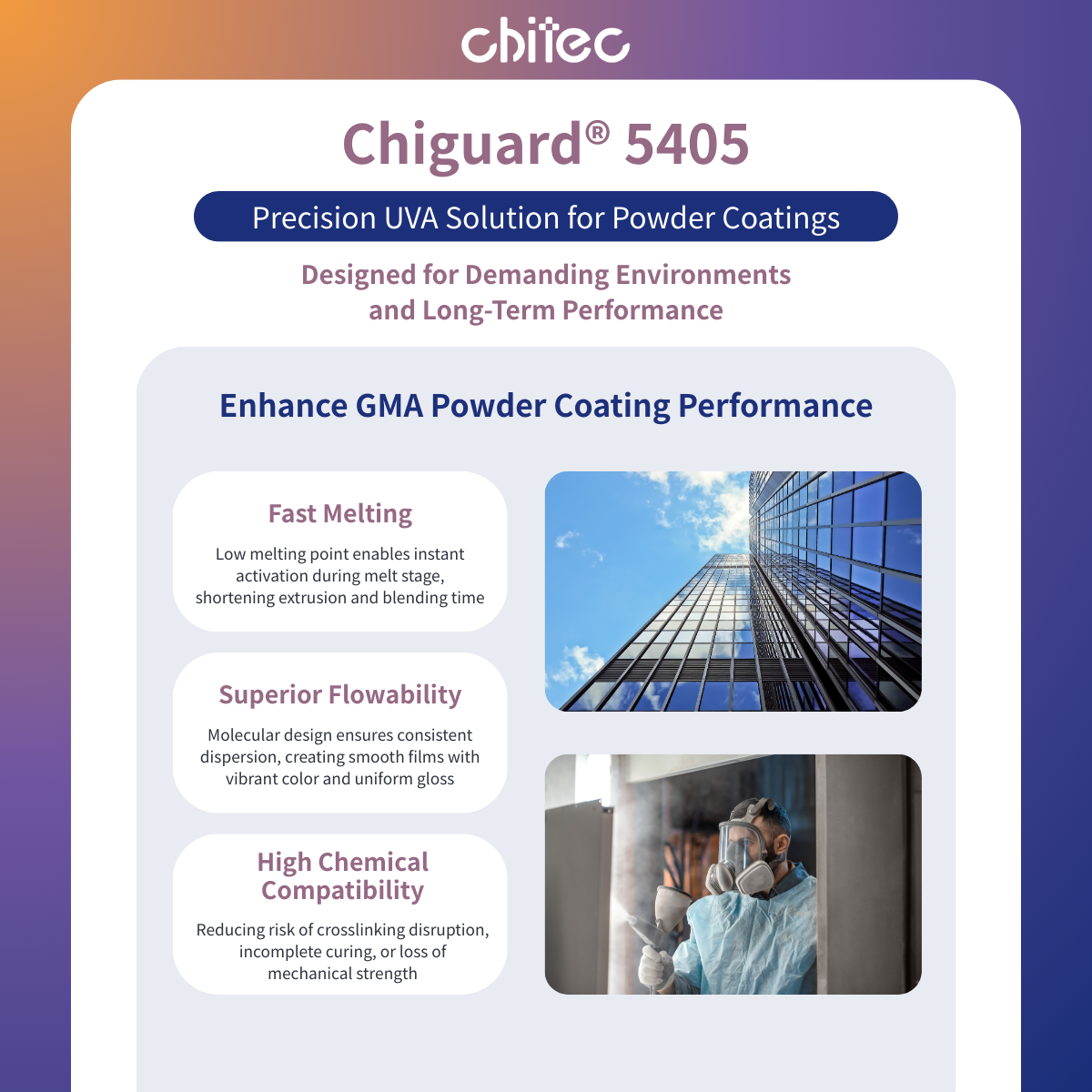

How Chiguard® 5405 Enhances GMA Powder Coating Performance

Chiguard® 5405 is optimized for the specific needs of GMA powder systems, offering a low melting point (70°C) and excellent dispersibility, delivering outstanding processing performance during melt mixing:

- Fast Melting → Low melting point enables instant activation during melt stage, shortening extrusion and blending time

- Superior Flowability → Molecular design ensures consistent dispersion, creating smooth films with vibrant color and uniform gloss

- High Chemical Compatibility → Resistant to reactions with anhydrides and metal catalysts, reducing risk of crosslinking disruption, incomplete curing, or loss of mechanical strength

Application Value in Offshore Wind Power Systems

Chiguard® 5405 may carry a higher material cost than conventional UV stabilizers, but in high-value, high-maintenance environments, it delivers long-term protection that offsets total lifecycle expenses.

Common offshore challenges include:

- Intense and continuous UV exposure

- High humidity and salt spray conditions

- Expensive and complex maintenance procedures

Recommended applications:

- Exterior topcoats for wind turbine towers using fluorocarbon or polyester powder systems — Helps extend service intervals and reduce the need for reapplication

- Electrical enclosures such as control panels and transformer housings — Suitable for long-term outdoor use where maintenance access is difficult

Cost-efficiency:

Chiguard® 5405 significantly reduces maintenance frequency and total ownership cost in offshore environments, making it a strategic investment for high-durability coating systems.

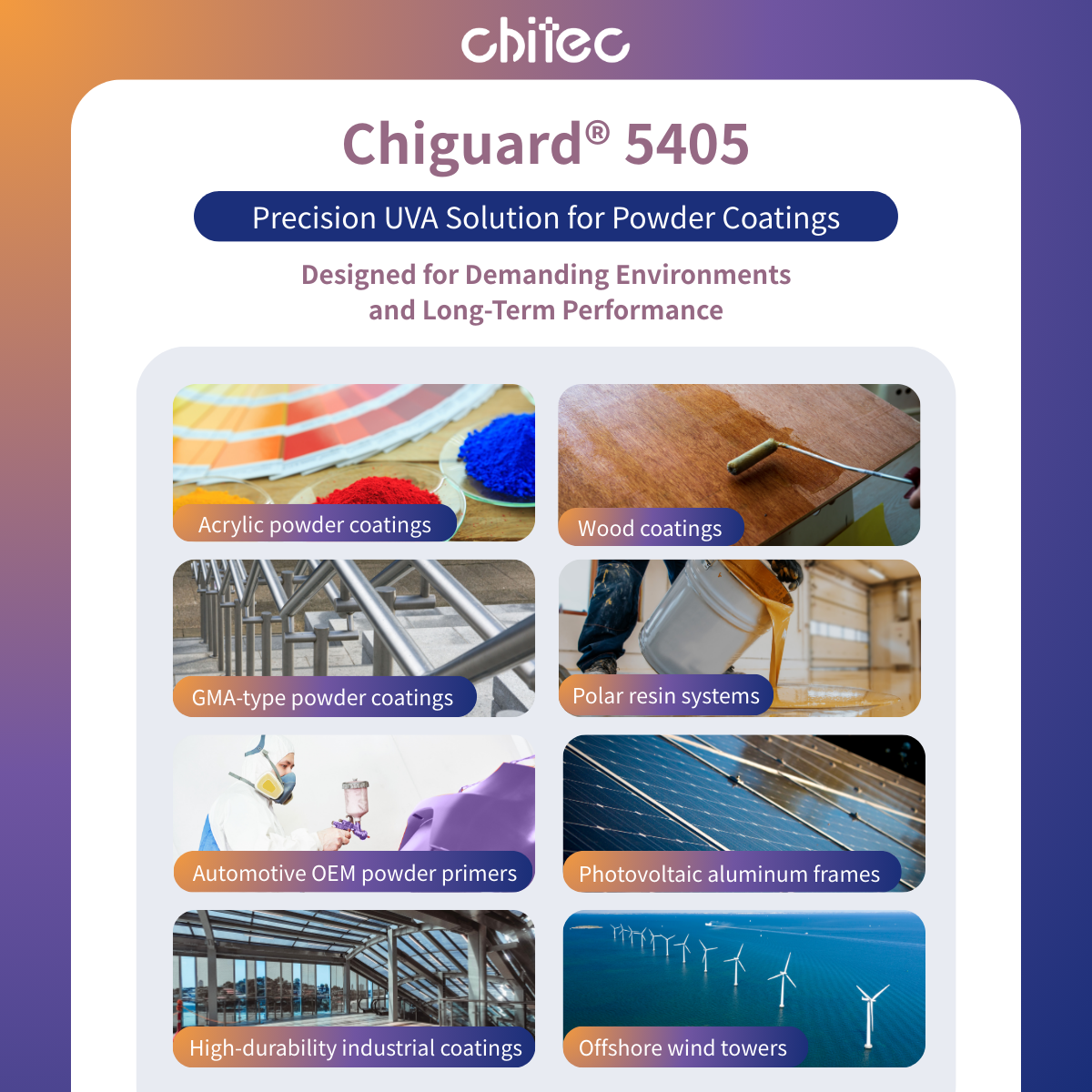

Applications of Chiguard® 5405

- Acrylic powder coatings

- GMA-type powder coatings

- Automotive OEM powder primers

- High-durability industrial coatings

- Wood coatings

- Polar resin systems

- Photovoltaic aluminum frames

- Outdoor construction materials, offshore wind towers, and electrical enclosures

If your formulation demands reliable long-term UV protection in extreme environments,

Chiguard® 5405 offers a high-performance solution tailored for advanced powder coatings and critical industrial applications.

📩 For technical details, samples, or customized recommendations, contact our team at: sales@chitec.com

建議您使用以下瀏覽器觀看本網站,

要下載瀏覽器,請直接點擊以下:以獲得最佳瀏覽效果。