What is Chiguard® WN Series?

[Anhydrous Liquid Additives]: Efficient, Stable, and Easy-to-Use – Engineered for Professional Coating Formulations

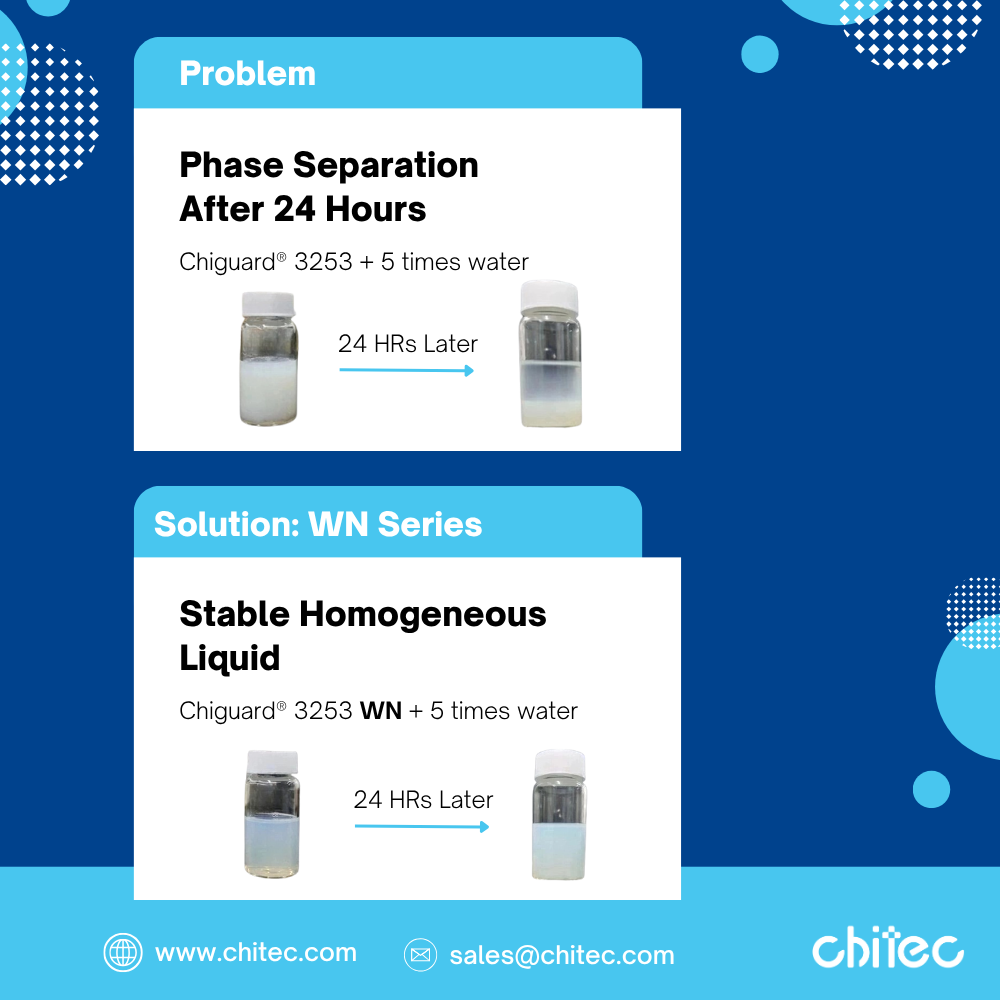

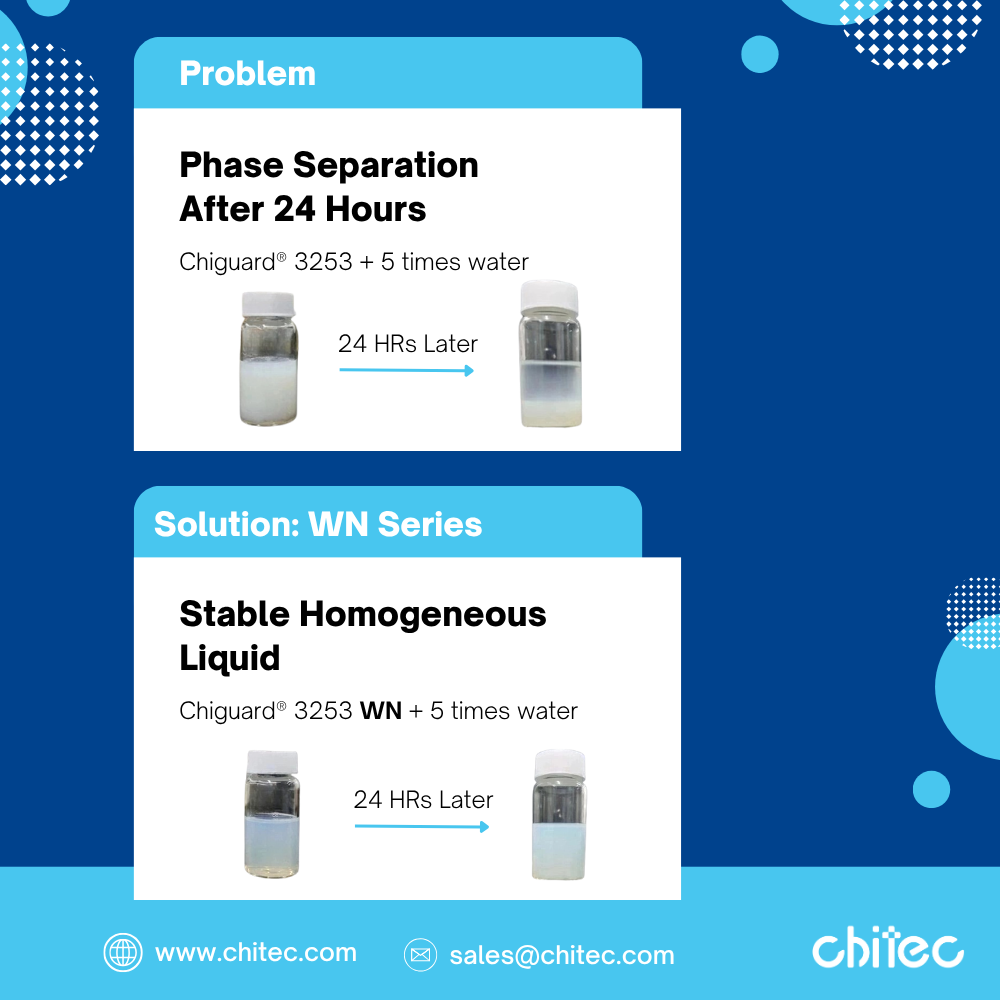

In today’s coatings market driven by environmental responsibility and high performance, the WN Series emerges as a tailor-made solution for formulators seeking flexibility, long-term stability, and outstanding compatibility. Developed by Chitec, the WN Series represents a line of liquid, anhydrous additives with high active content—providing a comprehensive and reliable solution for industrial, wood, and functional coatings.

【High-Stability Coating Additives】Five Key Technical Advantages of the WN Series

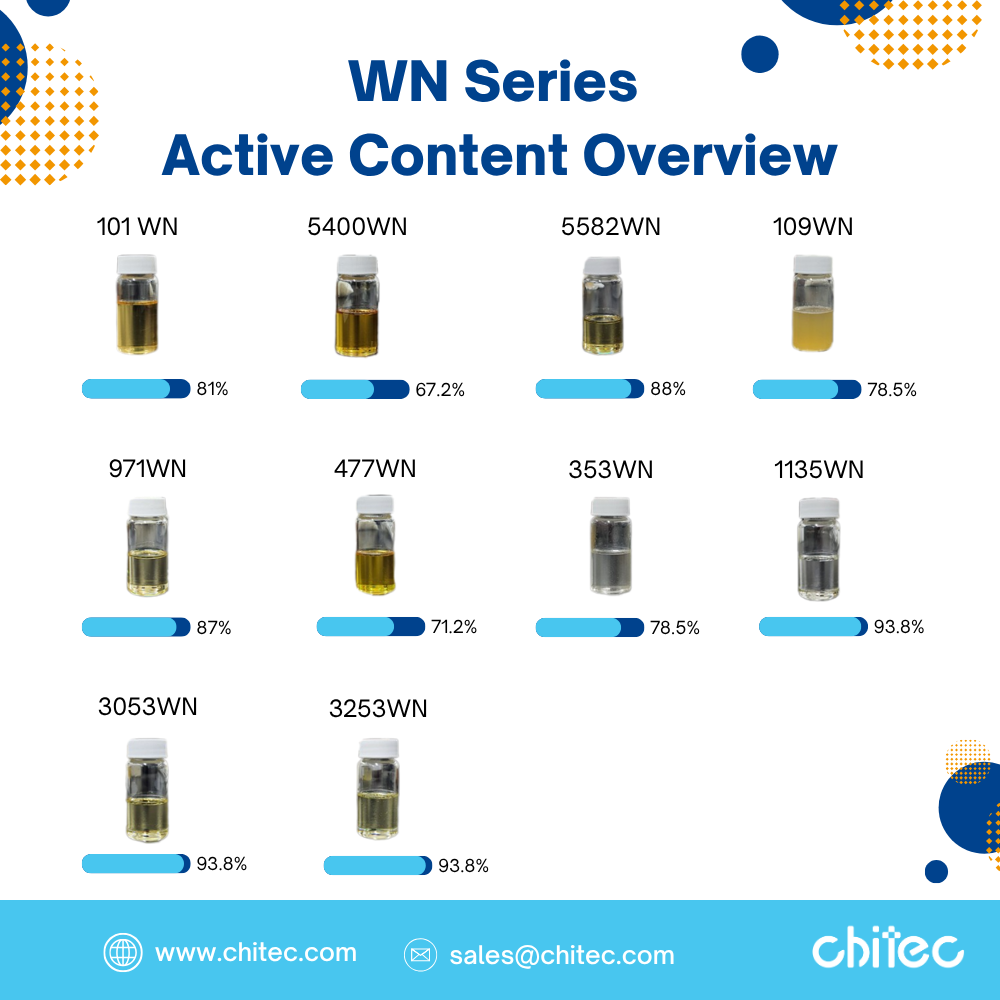

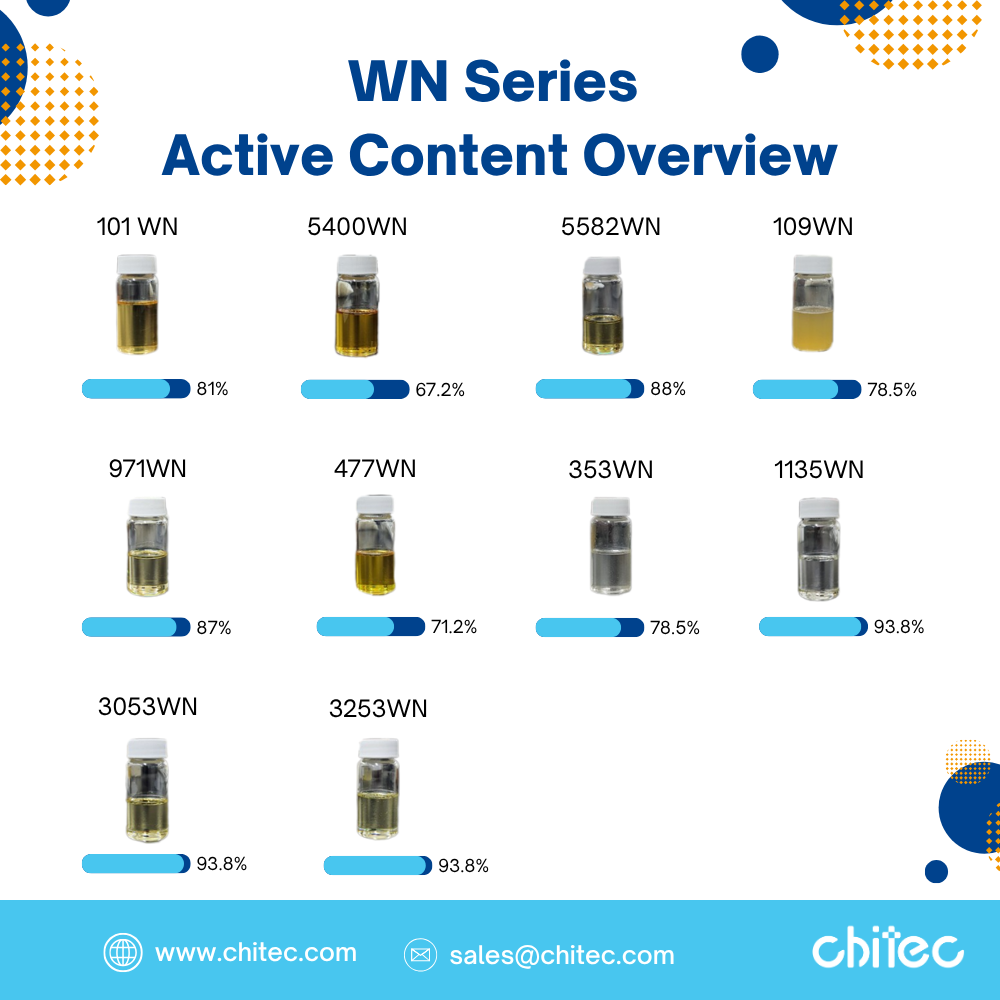

- Anhydrous High Concentration: Active ingredient levels of 67–94% enable significantly lower dosage requirements.

- Liquid Format: Ready-to-use without dispersion, simplifying processing and reducing formulation issues.

- Storage & Transport Stability: Resistant to sedimentation and degradation, ensuring consistent performance during long-term storage and global shipment.

- High Compatibility: Freely miscible with other stabilizers, minimizing incompatibility and enhancing synergistic effects.

- Low Volatility & Low Emulsifier Content (selected grades): Ideal for anti-fogging and stain-resistant systems; effectively minimizes foaming risk.

【WN Series Product Overview】Product Name, Key Features, and Applications

| Product Name |

Category |

Key Features |

Application |

| Chiguard® 1135WN |

Antioxidant |

- For water-based resins

- Low volatility

- Excellent resin compatibility

- Prevents fogging and staining

|

|

| Chiguard® 971WN |

UV Absorber |

- Liquid UV absorber tailored for waterborne PU

- Superior compatibility vs. traditional UVAs

- Excellent polyol solubility

- Non-yellowing during baking

|

- Water-based PU

- PU leather & films

- PU coatings

- PU panels

|

| Chiguard® 5582WN |

UV Absorber |

- High thermal & light durability

- Instantly miscible with waterborne resins

- No resin, diluent, or thickener—ensures compatibility

- Mixable with other Chitec stabilizers for a uniform emulsion

|

- Water-based Coatings

- Automotive Coatings

- Automotive OEM Base Coats

- Automotive Refinish Coatings

- Industrial Coatings

- Architectural Coatings

- Exterior Wood Protection (Clear and Tinted)

- Plastic Coatings

- Glass Coatings

- Water-based Industrial Coatings

- Adhesives

|

| Chiguard® 109WN |

UV Absorber |

- Based on hydroxyphenyl benzotriazole UV absorber

- Suitable for coatings and substrates requiring strong protection in the UVA wavelength range

- High performance with excellent thermal stability

- Outstanding photostability and superior UV absorption efficiency

|

- Coatings and substrates requiring strong UVA protection

- High-performance industrial coatings

- Decorative coatings

- Wood coatings

|

| Chiguard® 353WN |

HALS |

- Provides long-term thermal stability through a hindered phenol-like radical scavenging mechanism

- Significantly enhances performance when used in combination with UV absorbers

|

- A wide range of coating applications

|

| Chiguard® 3053WN |

UV Absorber |

- Delivers outstanding performance across various clear and pigmented coating systems

- Suitable for water-based applications

- Significantly improves thermal stability

- Excellent color retention

- Long-term thermal and UV stability

|

- Various clear and pigmented coating systems

- Wood coatings

- PUR systems

- UPES/styrene gel coats

- UV-curable systems based on acrylates and UPES

|

| Chiguard® 3253WN |

UV Absorber |

- Delivers outstanding performance across various clear and pigmented coating systems

- Suitable for water-based applications

- Significantly enhances thermal stability

- Excellent color retention

- Long-term thermal and UV stability

- Formulated with Chiguard® 5530 and Chiguard® 353

|

- Various clear and pigmented coating systems

- Transparent and light-colored applications

- Wood coatings

- PUR systems

- UPES/styrene gel coats

- UV-curable systems based on acrylates and UPES

|

| Chiguard® 477WN |

UV Absorber |

- Tris-resorcinol triazine

- Ideal for UVA-sensitive substrates or components, especially offering high absorbance in the UVA range (320–390 nm)

- Suitable for coatings exposed to high-temperature baking and/or extreme environmental conditions

- Meets long-term durability requirements

- Excellent photostability and thermal stability

- Outstanding solubility and compatibility

|

- Water-based coatings

- Liquid UV-curable coatings

- Industrial coatings

- Wood coatings

- Bake enamel systems

- Adhesives

|

| Chiguard® 101WN |

HALS |

- Especially suitable for polyurethane dispersions (PUDs) and alkyd emulsions where basic HALS (e.g., Chiguard® 353) are not effective

- Recommended for systems containing acidic catalysts, biocides, and similar additives

- Extremely low emulsifier content to minimize foaming issues

- Immediately miscible with water-based resins without affecting flow properties

- Free of resins and thickeners

|

- Water-based systems

- Polyurethane dispersions (PUDs)

- Alkyd emulsions

- Systems containing acidic catalysts and/or biocides

- PUD coatings for synthetic leather and textiles used in automotive seats and interior components

- Alkyd-based wood coatings

- PUD-based sealants and adhesives

|

| Chiguard® 5400WN |

UV Absorbers |

- Hydroxyphenyl triazine (HPT) UV absorber

- Specifically developed for high-performance water-based coatings

- Low volatility

- High thermal stability

- Excellent photostability

|

- High-performance water-based coatings

- Automotive OEM systems

- Automotive refinish systems

- UV-curable coatings

|

WN Series for Water-Based & High-Performance Coatings

- Industrial Coatings: Automotive, marine, heavy machinery, and metal protection

- Wood & Architectural Coatings: Exterior wood, clear finishes, floor coatings

- Functional Coatings: UV-resistant, anti-yellowing, weatherable, antimicrobial

- Water-Based Adhesives & Sealants: Ideal for PUD adhesives, sealants, and other heat/light-stable applications

- Advanced Additive Systems & Ink Formulations

Who Should Choose the WN Series?

- Export-Oriented Manufacturers: Ensure long-term stability during storage and shipping

- Coating Innovators & R&D Teams: Demand maximum flexibility and tunable performance in formulations

- High-Performance Coating Brands: Require top-tier UV and thermal protection for premium products

Further Reading: Waterborne UVAs and HALS – Chiguard® WB

📩

Discover how the WN Series can boost your formulation stability and market success.

Contact our sales team today:

Contact Us

建議您使用以下瀏覽器觀看本網站,

要下載瀏覽器,請直接點擊以下:以獲得最佳瀏覽效果。