R-gen® 919|Liquid Photoinitiator Engineered for Dark UV Inks

Overcoming Carbon Black Shielding & Curing Bottlenecks

Curing Challenges in Dark UV Systems

In industrial inkjet printing, electronic marking, and premium packaging applications, achieving “deep and uniform black” is not only a visual requirement but also a significant formulation challenge. To obtain ideal opacity, black UV inks and coatings often require high carbon black loading. However, carbon black exhibits strong UV absorption, effectively blocking light penetration through the coating. This severely limits photoinitiator activation, resulting in incomplete curing, residual tackiness, surface defects, and compromised downstream processing.

Such issues can degrade product appearance, trigger customer complaints, and increase the risk of returns. These challenges are particularly critical in thick films, high-pigment, and deep-color formulations, placing triple pressure on formulation stability, production efficiency, and quality control.

Limitations of Conventional Photoinitiators

Conventional solid photoinitiators, such as Chivacure® 169, often face poor solubility and dispersion in dark, high-pigment systems, causing localized under-curing and sedimentation. This not only reduces coating uniformity and finished product quality but also significantly impacts formulation storage stability. In applications such as inkjet printing or precision coating, these issues can lead to nozzle clogging and production downtime, affecting yield and throughput.

Key Considerations When Developing Dark UV Systems

Developing dark UV systems poses greater formulation challenges than standard colored systems. To meet visual performance, process stability, and regulatory compliance, two factors are key:

Dark formulations often rely on carbon black to achieve high opacity; however, excessive use can severely block UV penetration, making it difficult for photoinitiators to trigger the curing reaction. Balancing opacity and transmittance is the first step in optimization.

If photoinitiators are not fully dissolved or evenly dispersed, localized curing defects and surface issues occur—hurting production continuity and equipment efficiency.

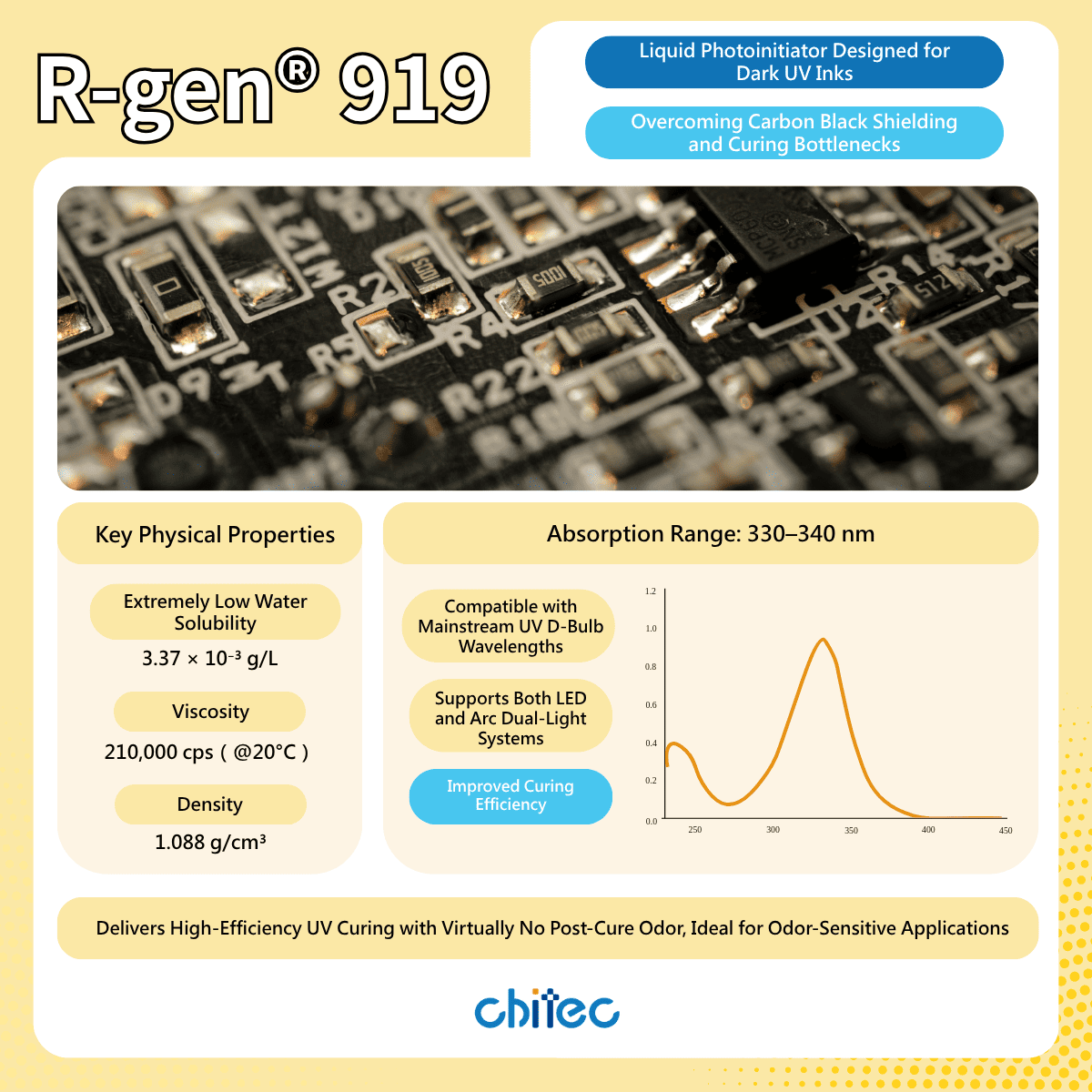

In dark UV inks and high-pigment coatings, carbon black’s opacity hinders light penetration. Solid PIs (e.g., Chivacure® 169) show low solubility, causing instability and nozzle clogging. R-gen® 919 is fully liquid and miscible with most acrylates—ensuring no separation, turbidity, or sedimentation even under extremely high pigment content.

Key Performance Data:

- Solubility: Fully miscible with acrylate resins; aqueous solubility 3.37×10⁻³ g/L

- Viscosity & Density: 210,000 cps (20°C), 1.088 g/cm³ (fit for high-precision coating/inkjet)

Comparable photoreactivity to high-performance PIs under both ARC and LED (365/395 nm). Even in severe UV absorption by carbon black, R-gen® 919 initiates polymerization reliably—ideal for high-speed inkjet, UV coatings, and PCB marking.

- Curing speed: 10–20 m/min (high-opacity black)

- UV absorption peak: 330–340 nm (D-bulb main output)

Traditional p-morpholinoacetophenone PIs may release strong odor after cure. R-gen® 919 achieves high curing efficiency with virtually no post-cure odor, suitable for odor-sensitive uses.

Key Applications

-

1) Black UV Inkjet

- Challenge: High carbon black blocks UV; solid PIs have poor solubility & sedimentation → nozzle clogging.

- Solution: Fully liquid R-gen® 919 improves miscibility & storage stability, reducing sedimentation/clogging and enabling high-speed precision printing.

-

2) UV Inks for PCB Marking

- Challenge: High-opacity PCB inks suffer UV attenuation and poor cure; solid PIs sediment → lower yield.

- Solution: R-gen® 919 maintains superior reactivity under high carbon black, enabling fast, tack-free curing and stable dispersion—ideal for electronic-grade mass production.

-

3) High-Pigment UV Coatings

- Challenge: High pigment concentration reduces curing efficiency; traditional photoinitiators may precipitate or stratify, compromising coating quality.

- Solution: R-gen® 919 provides stable curing initiation under high-opacity conditions and is compatible with multiple resin systems, ensuring uniform, reliable film formation.

-

4) Non-CMR UV Systems

- Challenge: Many advanced markets (e.g., EU, North America) restrict CMR 1(b) substances, making traditional photoinitiators unsuitable.

- Solution: R-gen® 919 contains no CMR 1(b) substances, offering an ideal choice for globally compliant high-performance formulations.

CMR 1B = Substances presumed to be carcinogenic, mutagenic, or toxic to reproduction. If a raw material is categorized as CMR 1B, it is restricted or banned in the EU market (especially for food contact, personal care, and children’s products). Many customers explicitly require “no CMR 1B substances”. Regulations such as REACH, RoHS, and Ecolabel also emphasize exclusion of CMR substances.

Contact Us

For samples, technical support, and customized formulation consulting: